Vesla s.r.o., the main manufacturing plant of the Unitron Group, is located in the industrial area of Kladno, 20km from Prague, with fast access to the highways R7 and D5 and at only 14km distance from the Prague international airport. The company was founded in 1994 and went through different stages to become the flexible production unit of today.

Currently, more than 1500m² are dedicated to manufacturing activities and about 750m² to warehousing (400 pallets). Our broad range of activities includes:

- Purchase and receipt of components

- Printed board assembly services

- Sheet metal processing

- Subsystem assembly services

- Test and measurement

- Quality control

- Warehousing, packing and expedition

Our strength is to offer small and mid-range series at an affordable price and with guaranteed quality: we produce series ranging from a single piece up to high volume production. Based on the ordered quantities a semi-automated or fully-automated test flow is implemented.

For each challenge, we want to be a competent and competitive partner, here follows a summary of our capabilities and approach in some of our departments.

Vesla s.r.o. stands for open communication with its customers. Through a focused approach we realize their expectations in the most flexible and fastest way, while offering stable and sustainable quality.

Our services cover all activities from product idea to finished goods delivery:

- Full or partial project management services to assure delivery within time and budget

- Research & Development

- Production alignment: all data required for production is imported in our ERP and shop floor systems and multidisciplinary teams are trained to assure smooth startup of projects

- Flexible production flow: from component purchase and receipt, through the manufacturing process to shipping of end-products, all activities are centralized in 1 production location thus assuring short lead-times and fast reaction to customer requests

- Product maintenance: in-house diagnostic and repair services

Printed board assembly services

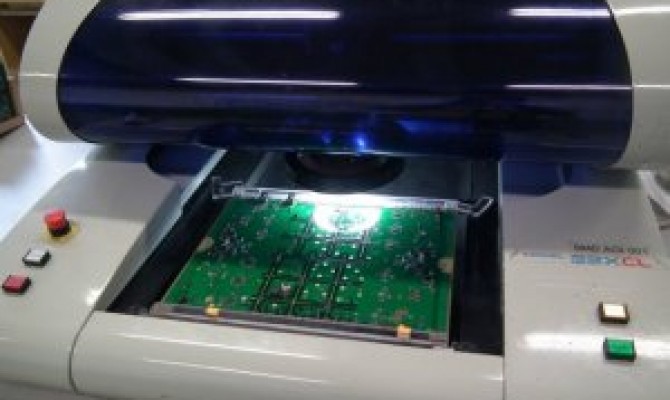

This department is equipped with a modern SMD line: our main production line JUKI has a screen printer, 4 pick-and-place machines and a reflow oven, it can handle SMD components up to 0201 size. We produce series ranging from single piece up to high volume quantities.

On the output of the SMD lines Automated Optical Inspection (AOI) is implemented. We can handle the reflow and wave soldering processes. We have experience in both paste and glue designs. In this department a strict ESD policy is maintained to guarantee a 100% antistatic working environment.

Sheet metal processing

Our multifunctional and reliable machine park allows in-house production of tinned sheet metal covers and frames, all necessary equipment

for cutting, punching, bending and welding is present:

- Centrifugal pressing machines (1 x 50 tons, 2 x 40 tons, 3 x 10 tons)

- Hydraulic pressing machines (2 x 15 tons)

- Welding machine

Our skilled operators are involved from the start of a customer project and can assist in design for manufacturing, die exchange time reduction and cost-reduction programs.

Our customers always enjoy the luxury of our flexibility and our customer-oriented approach

Subsystem assembly services

Our operators are continuously trained to accomplish high qualitative assembly of electronic, electrical, mechanical and cabling components using wave or manual soldering to offer our customers the most competitive solution.

The performance of our employees is monitored in real-time, continuous improvement is realized by registering all occurring problems and providing direct visual feedback by Pareto- and control-charts.

Test and measurement

A profound analysis of the customers testing requirements is made during the project transfer phase. Based on this input the optimal test methodology is selected and implemented: manual, semi-automatic or full automatic testing.

It is our aim to offer the best quality at the lowest cost by the correct level of automation, this results in avoiding operator related mistakes and reduces sincerely the needed test times.

Besides RF related tests, other test setups (for example a High-Voltage test stand) are available in Vesla s.r.o.

Our test engineers have built up their experience implementing test setups for our range of RF products. The result is an extensive knowledge of network and spectrum analysers and integrated testbenches (based on National Instruments software).

The results of these automated tests are present in a relational database structure and can be exported to a desired format (html, xml, …).

Where quality is a state-of-mind

- Incoming inspection based on the AQL methodology (quality at the source)

- In-process testing during the different assembly and testing stages (progressive inspection)

- Real-time registration and follow-up of non-conformities

- Outgoing quality control based on the AQL methodology

- Full product traceability with storage of records up to 20 years

- Weekly quality meetings to close the feedback loop and assure continuous improvement

- We offer our customers flexibility to request other inspection and quality control methods.